Metal is an excellent material, we can assemble a variety of structures, with high reliability and durability. From metal we can easily make not only small lightweight stairs, but also solid construction of any complexity.

Stairs fabrication assembled according to instructions, will benefit all the architectural features of the house, will fit perfectly into any interior, both inside and outside the house. The main advantage of the metal staircase is that it can easily be assembled on their own, without using specific materials or tools. Staircase welding will not take much time, but it will please you for many years.

Staircase fabrication, is important to make sure that the thickness of metal is not less than 3 mm, and its surface should be grooved. Safe staircase, should have a special anti-slip coating. It can be a mat of rubber, overlay made of crumb rubber or abrasive adhesive tape. Such coatings will protect from injury and serve as a decoration of the external staircase.

The staircase fabrication and welding is a big part of the work, however not the most important. Do not underestimate the role of finishing. It will provide ready-made structure reliable protection against metal corrosion and give the staircase great look.

At this stage, the final processing of all welds, protruding parts, sharp corners and roughness. To this end, it is necessary to use a grinder with an emery wheel, which will help to thoroughly grind everything. Grinding work will be performed once the staircase is assembled, on a metal surface.

Also, you have to choose the suitable roughness, to give your metal stairs a fine surface, there are two ways of doing it: by grinding or by air-blast finishing. For this process, metal stairs are held in compression steel cage, in which you attach you assembling mat. This process will require a high skill level of fabrication and metal working, and it will allow you to obtain a satisfactory finish on your staircase.

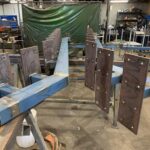

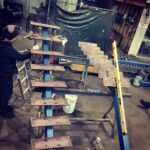

A staircase fabrication should begin with the manufacture of the frame. To do this, you need to take the channels, whose length should be calculated in advance at the preparatory stage, and put them on the rib. Next, using an electric arc welder, weld the corners, which will be the basis for installing the steps.

On top of them are mounted steel steps, made of smooth metal with slots. You can also use any other material that is provided by your design project. It is important that all the steps are strictly parallel to the floor, so pay attention to right angles.

Railing and railings

Railing and railings are made by welding square metal pipes, and after they should be attached to the right place using all the same welding.

At the final stage of the staircase is installed in the already prepared for this opening, and then securely fastened with anchor bolts.

Stairs fabrication final stage

At the final stage it remains only to deal directly with the decoration of the staircase. For example, you can use artistic forging for the railing, bright color of paint or a rare type of wood for making steps – please use your imagination. The main thing to remember is that the internal staircase should blend in with the interior of the room in which it is located, and the outdoor staircase should not stand out from the overall architecture of the house.

Stairs is very important part of a house. They are required for the entrance to the house, to the first floor, attic or attic. For the most part, people choose a metal staircase. Because of the advantages of metal, its strength, durability, the ability to give any shape.