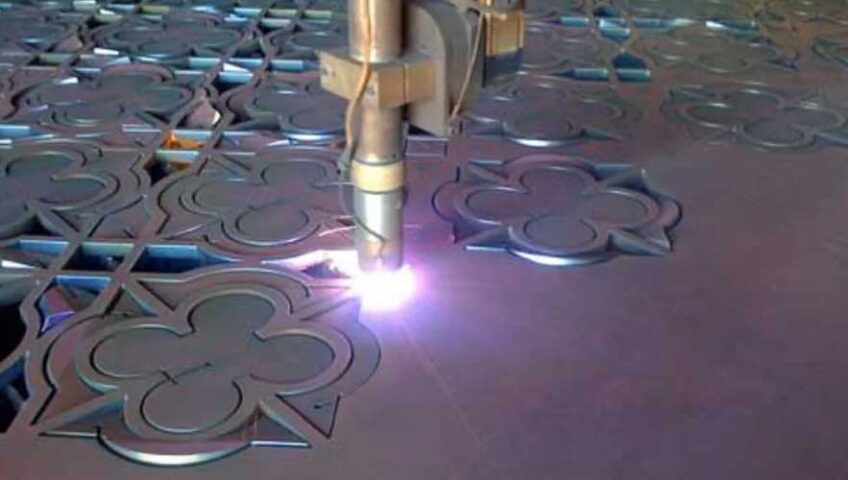

Laser cutting technology has been a transformative force in the world of metal fabrication, particularly in steel and stainless steel. More than just a tool for cutting, it serves as an instrument of design, carving intricate patterns and enabling the most complex of architectural and engineering visions to come to life. This article dives deep into the realm of laser cutting design in steel and stainless steel, revealing not just the technical intricacies but also the artistic possibilities that can be unleashed.

Development of laser steel cutting design

Steel, an alloy primarily of iron and carbon, offers an excellent combination of strength and versatility. These traits make it a perfect candidate for laser cutting, which can precisely shape steel sheets into complex geometries and fine details that other cutting methods often can’t achieve. The process begins with a computer aided design (CAD) model that instructs the laser cutter on how to create the design. From industrial components to intricate art installations, the scope of laser cutting design in steel is vast and continually expanding.

Stainless steel holds a special place in the world of laser-cut design. Its resistance to corrosion and rust makes it an ideal material for outdoor installations, industrial applications, and kitchenware, among others. Laser cut designs in stainless steel not only look sleek but also last longer, maintaining their appearance through various environmental conditions. The advent of high-precision lasers has allowed for intricate designs that can be as complex as they are durable.

Design Principles in Laser Cutting Steel Sheet

When working with laser cutting steel sheet design, certain principles can help guide both the aesthetic and functional aspects of a project:

1. Complexity vs. Simplicity

The laser cutter’s precision allows for complex patterns, but it’s essential to strike a balance. Extremely intricate designs can increase both time and costs.

2. Material Thickness

The design must be compatible with the material’s thickness. While lasers can cut through thick steel sheets, it’s often more time-consuming and costly. On the flip side, designs requiring high precision are better suited to thinner sheets.

3. Cut Width

It’s crucial to consider the laser’s cut width, often referred to as the “kerf.” A tiny amount of material is removed during cutting, which can affect the final dimensions of the design.

4. Geometric Tolerance

Lasers are highly accurate, but even they have limitations in maintaining geometric tolerances. These should be considered during the design phase to ensure the end product meets specifications.

Design Software and CAD Systems

Modern laser cutting machines are typically compatible with various CAD systems, enabling complex designs to be easily transferred from software to machine. Software like AutoCAD, SolidWorks, and Adobe Illustrator can be used to create designs that can then be fed into the laser cutter, thereby streamlining the manufacturing process.

Applications of Laser Cutting Design in Steel and Stainless Steel

The applications for laser cutting steel sheet design in steel and stainless steel are endless, spanning across various sectors:

1. Art and Sculpture

Artists often use laser-cut steel and stainless steel to create intricate sculptures or installations that captivate audiences.

2. Architecture and Construction

From decorative elements on buildings to functional components like brackets and supports, laser-cut steel is frequently used in architecture and construction.

3. Automotive Industry

Here, the precision of laser cutting is crucial for creating parts that not only look good but also perform optimally.

4. Furniture Design

Modern furniture design frequently incorporates laser-cut steel or stainless steel, both for structural components and decorative elements.

5. Signage and Branding

Businesses commonly use laser-cut steel designs for signs and logos, leveraging the material’s durability and the technology’s precision.

Custom Laser Cutting Services

Today, a multitude of services offer custom laser cutting in steel and stainless steel, allowing you to bring your unique designs to life. These services often provide end-to-end solutions, starting from the design phase to the final cutting, polishing, and delivery. Such providers often have designers on staff who can help refine your ideas into laser-compatible designs.

Laser cutting design in steel and stainless steel has opened up a world of possibilities in both industrial applications and artistic expressions. The technology allows for intricate patterns and precise cuts, making steel and stainless steel more versatile than ever before.

As the technology continues to advance, we can expect even greater capabilities and design opportunities. Whether you’re an artist dreaming up your next masterpiece, an engineer designing a critical component, or a homeowner looking to add a unique decorative element to your space, the world of laser cutting design in steel and stainless steel offers limitless possibilities waiting to be explored.