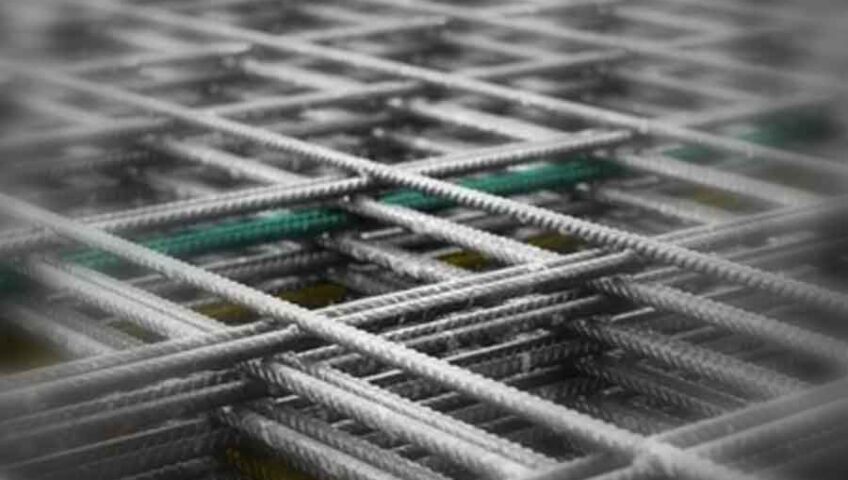

Steel mesh, known for its versatility, durability, and strength, serves as a critical component in numerous applications, from construction reinforcement to decorative elements. Bending steel mesh, while seemingly straightforward, requires precision and the right approach to maintain its structural integrity. Let’s delve into the essentials of bending steel mesh effectively and safely.

Key Characteristics of Steel Mesh

Understanding steel mesh’s intrinsic properties is paramount. Steel mesh comes in various sizes, weights, and patterns, with welded and woven types being the most common. These attributes directly influence the bending technique required.

Tools Essential for Bending Steel Mesh

- Mesh Bending Pliers

Designed specially for steel mesh, these pliers give users the grip and leverage necessary to bend small sections. - Workbench with a Vise

Provides a stable platform for holding and bending larger mesh sections. - Hammer

Useful for tapping and ensuring a flat finish post-bending. - Protective Gear Safety gloves and goggles protect against sharp mesh edges and fragments.

Step-by-Step Approach to Bending Steel Mesh

- Safety Precautions: Start by wearing protective gear. Steel mesh edges can be sharp, and protective gloves prevent cuts, while safety goggles shield eyes from any fragments.

- Measurement and Marking: Determine the bending point or region on the steel mesh. Marking isn’t always feasible on mesh, but visual approximation can guide the bending process.

- Positioning on Workbench: For larger bends, place the steel mesh on a workbench. The mesh section you want to bend should be freely suspended, with the remainder held securely by a vise.

- Bending with Pliers: For small bends, grip the desired section with bending pliers and apply pressure. Ensure even force for a uniform bend.

- Hammering for Precision: After the initial bend, place the mesh on a flat surface and lightly hammer any uneven sections to achieve the desired angle.

Common Challenges and Their Solutions

- Uneven Bends: If a bend is uneven, it might be due to inconsistent pressure during bending. Solution: Use the hammer to gently tap and rectify the bend or employ a more stable platform for bending.

- Mesh Distortion: Bending can sometimes distort the mesh pattern. Solution: Ensure even pressure distribution during bending and avoid over-bending.

- Sharp Edges: Post bending, steel mesh can develop sharp edges. Solution: Use a file to smoothen any protruding or sharp points for safety.

Advanced Bending Techniques

For intricate projects or designs, advanced bending methods might be necessary. Hydraulic mesh benders, although more expensive, can produce consistent and precise bends, especially for thicker meshes. These machines are typically used in industrial settings but can be rented for specific projects.

Applications of Bent Steel Mesh

Once mastered, the skill of bending steel mesh opens the door to a plethora of applications:

- Construction Reinforcement: Bent steel mesh reinforces concrete, ensuring robust and long-lasting structures.

- Decorative Elements: From garden features to artistic installations, the malleability of steel mesh offers immense creative potential.

- Fencing and Enclosures: Bent mesh can contour to landscapes, providing effective barriers or enclosures in diverse settings.

Final Thoughts on Bending Steel Mesh

Bending steel mesh is an invaluable skill for both professionals and DIY enthusiasts. With the right tools, techniques, and safety precautions, you can manipulate steel mesh to suit a myriad of applications. As with any craft, practice enhances proficiency. Whether you’re reinforcing a structure, crafting a decorative piece, or erecting a protective barrier, bending steel mesh with precision will ensure optimal results and longevity.