- Introduction to Steel Laser Cutting Service

- Understanding Steel Laser Cutting Technology

- The Role of Steel in Construction

- Comparing Traditional Steel Cutting with Laser Technology

- Structural Steel Fabrication and Its Significance

- Innovations in Steel Laser Cutting

- Case Studies: Successful Projects Using Steel Laser Cutting

- Challenges and Solutions in Steel Laser Cutting

- Selecting a Steel Laser Cutting Service Provider

- Conclusion and Future Outlook

- FAQs

Melbourne’s Construction Industry

As Melbourne continues to grow and transform, the role of advanced technologies in its construction industry becomes increasingly significant. Among these, steel laser cutting service stands out as a revolutionary force, reshaping the skyline of this vibrant city. This cutting-edge technology, known for its precision and efficiency, is playing a pivotal role in the construction of Melbourne’s modern architectural marvels, from towering skyscrapers to innovative infrastructure projects.

Steel laser cutting services bring a level of detail and accuracy previously unattainable with traditional cutting methods. This has not only enabled Melbourne’s architects and engineers to push the boundaries of design but has also significantly improved the speed and efficiency of construction projects across the city. As Melbourne strives for sustainability and innovation in its growth, the integration of such advanced techniques is crucial. The city, known for its mix of historic and contemporary architecture, now sees a new era where steel laser cutting contributes significantly to both aesthetic and structural integrity.

In the heart of Melbourne, steel laser cutting services are not just about shaping metal; they are about creating a legacy of resilient and awe-inspiring structures. Be it the intricate designs of public art installations or the robust framework of commercial buildings, the precision of laser cutting is evident throughout the city. For Melbourne’s residents, understanding the impact of this technology is key to appreciating the intricate work behind the city’s evolving landscape. This article delves into the intricacies of laser cutting, its impact on Melbourne’s construction industry, and what the future holds for this innovative technology in one of Australia’s most dynamic cities.

Understanding Steel Laser Cutting Technology

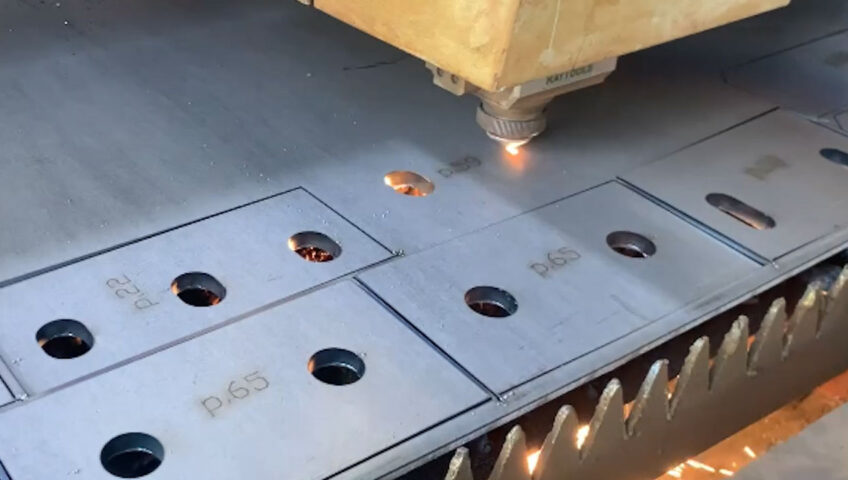

Laser cutting utilizes a concentrated beam of light to cut through materials, and in the steel industry, it’s a game-changer for cutting and shaping steel components. This technique surpasses traditional methods in accuracy, efficiency, and versatility, making it essential for intricate and precise structural designs. The role of steel laser cutting service extends beyond mere cutting; it encompasses the creation of complex and precise shapes that are pivotal in structural steel fabrication.

The Role of Steel in Construction

Steel stands as a fundamental material in the construction industry, revered for its strength, durability, and versatility. Its unique properties, including high tensile strength and resistance to environmental stresses, make it an ideal choice for a wide range of construction projects. From skyscrapers to bridges, steel’s role is irreplaceable, providing the backbone for modern infrastructures.

Comparing Traditional Steel Cutting with Laser Technology

Traditional steel cutting methods, such as mechanical sawing or torch cutting, have been the industry standard for decades. However, they often fall short in terms of precision and efficiency. Laser cutting, on the other hand, brings a level of accuracy that traditional methods cannot match, producing cleaner cuts and more complex shapes with minimal waste. This comparison highlights the transformative impact of laser technology in steel cutting, offering a more refined and sustainable approach.

Structural Steel Fabrication and Its Significance

Structural steel fabrication is a critical process in the construction industry, involving the cutting, bending, and assembling of steel to create different structures. The precision and efficiency of steel laser cutting service play a pivotal role in this process, enabling fabricators to produce components with high accuracy and consistency. This not only enhances the quality of the final structures but also significantly reduces material wastage and project timelines.

Innovations in Steel Laser Cutting

Steel laser cutting has undergone significant advancements in recent years. Innovations such as increased laser power, automation, and improved precision have greatly enhanced the capabilities of laser cutting machines. These technological strides have not only improved the speed and efficiency of cutting processes but also expanded the possibilities for intricate and complex designs in steel construction. The evolution of laser technology continues to shape the future of steel fabrication, promising even more groundbreaking applications.

Case Studies: Successful Projects Using Steel Laser Cutting

Exploring real-world applications provides a clear perspective on the impact of steel laser cutting services in the construction industry. Several landmark projects, including the construction of iconic buildings and complex infrastructures, have leveraged the precision and efficiency of laser cutting. These case studies not only illustrate the practical applications of laser cutting in steel construction but also highlight its role in achieving architectural marvels and engineering feats.

Challenges and Solutions in Steel Laser Cutting

Despite its many advantages, steel laser cutting is not without its challenges. Issues such as material thickness limitations, cutting speed, and energy consumption are areas of concern. However, the industry continues to find innovative solutions to these challenges, such as developing more powerful lasers and optimizing cutting parameters. These solutions not only address current limitations but also pave the way for more efficient and sustainable practices in steel laser cutting.

Selecting a Steel Laser Cutting Service Provider

Choosing the right steel laser cutting service provider is crucial for the success of any construction project. Factors such as technology used, experience, project portfolio, and customer service should be considered. It’s important to partner with a provider that not only has advanced laser cutting capabilities but also understands the nuances of structural steel fabrication. This section will offer insights into the criteria that should guide this selection process, ensuring the best possible outcome for your projects.

Conclusion and Future Outlook

Steel laser cutting service has undoubtedly transformed the steel construction industry, offering unmatched precision, efficiency, and flexibility. As we look to the future, the ongoing advancements in laser technology are set to further revolutionize this field, promising even more innovative applications and efficiencies. The final section will summarize the key points discussed in the article and provide a glimpse into the future of steel laser cutting in the construction industry.

FAQs

- What are the main advantages of steel laser cutting over traditional methods?

Steel laser cutting offers unparalleled precision, efficiency, and flexibility compared to traditional cutting methods. It allows for intricate and complex designs, reduces material wastage, and enhances the overall quality of the final product. Moreover, laser cutting is faster and more energy-efficient, making it a more sustainable choice for the environment. - How does steel laser cutting contribute to structural steel fabrication?

In structural steel fabrication, steel laser cutting plays a crucial role in producing precise and consistent components. This precision is essential for ensuring the structural integrity and aesthetic quality of buildings and infrastructures. Laser cutting also allows for the creation of custom and complex shapes, which are often required in innovative architectural designs. - What should I look for when selecting a steel laser cutting service provider?

When selecting a steel laser cutting service provider, consider their technology, experience, quality of work, and customer service. Look for providers with advanced laser cutting machines, a strong portfolio of projects, positive client testimonials, and a commitment to deadlines and quality. Additionally, assess their ability to handle your specific project requirements. - Are there limitations to what steel laser cutting can achieve?

While steel laser cutting is highly versatile, it does have limitations, such as thickness constraints and material compatibility. The thickness of steel that can be effectively cut depends on the power of the laser machine. Additionally, certain materials or extremely intricate designs may pose challenges. However, ongoing technological advancements continue to expand the capabilities of laser cutting. - How does steel laser cutting impact the overall cost of a construction project?

Steel laser cutting can be cost-effective in the long run. While the initial investment in laser cutting technology might be higher compared to traditional methods, it offers greater efficiency, precision, and lower material wastage. These factors can lead to reduced overall project costs, especially in complex projects where precision is critical.