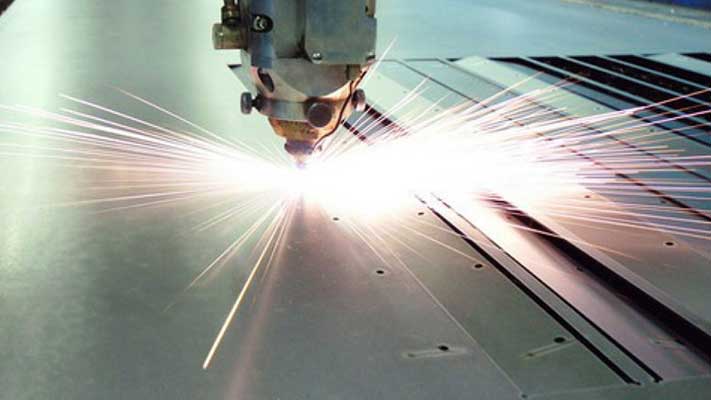

Laser cutting technology has drastically changed the way industries deal with metal fabrication. This advanced technique is known for its precision, versatility, and surprisingly, its cost-effectiveness when viewed in the scope of its benefits. However, understanding the costs associated with laser cutting—be it for sheet metal or bulkier materials—is critical for both project planning and execution. This comprehensive guide will delve into the factors that influence sheet metal laser cutting cost as well as general metal laser cutting costs, thereby helping you make an informed decision for your next project.

Sheet Metal Laser Cutting Cost – Overview

One of the most common applications of laser cutting technology is in the realm of steel metal fabrication. When it comes to sheet metal laser cutting, several factors come into play in determining the overall cost.

These can include:

Material Type

Different metals have different costs and ease of cut. Stainless steel laser cutting, for example, is generally more expensive to work with than aluminum due to material cost and the laser’s power requirements.

Thickness of Material

The thickness of the material you’re looking to cut can also greatly affect the price. It’s usually more expensive to cut thicker material; for example, cutting 2mm thick sheet metal will cost less than cutting 20mm thick metal.

Design Complexity

Simple designs with fewer cuts and corners will naturally cost less than intricate patterns requiring higher precision and more machine time.

Volume

Economies of scale are also a factor. Higher volumes often reduce the per-unit cost of each piece cut.

Metal Laser Cutting Cost – Beyond Sheet Metal

Metal laser cutting isn’t limited to sheet metal; it also encompasses thicker materials that are used in other industries like construction, aerospace, and heavy machinery. For these applications, the same factors affecting sheet metal cost apply, although they might scale differently.

Material and Power Requirements

The type of metal you’re cutting can significantly impact the cost. For instance, carbon steel is generally easier and less expensive to cut than stainless steel due to its lower reflectivity and higher absorption of the laser beam.

Time and Labor

Thicker materials often require slower cutting speeds, which translates to more time and higher labor costs.

Technology’s Impact on Cost

CNC Laser Cutting

The advent of Computer Numerical Control (CNC) technology has allowed for even more precision in laser cutting. CNC laser cutting often reduces the need for further post-processing, thereby saving on additional labor and finishing costs.

Fiber Laser Cutting Technology

The introduction of fiber laser technology has revolutionized the speed and efficiency of laser cutting, often making it more cost-effective even for more intricate designs.

More Factors

Setup Costs

Regardless of whether you’re working with sheet metal or bulk metal, setup costs can be a significant part of the total cost, especially for smaller runs. Some companies offer discounted setup costs for larger production volumes.

Tolerance Levels

The required tolerance level of your project can also affect the cost. Tighter tolerances require more precision, which can result in additional time and, consequently, higher costs.

Geographic Location

Often overlooked, the geographic location of your chosen metal laser cutting service can impact costs due to shipping and handling fees.

Cost Comparisons

It’s often beneficial to compare the costs of laser cutting to other methods like plasma cutting, water jet cutting, or traditional mechanical cutting. While the upfront costs may be higher for laser cutting, the precision and reduced need for post-processing can make it more cost-effective in the long run.

Getting Quotes and Estimates

Given the variables that can influence the cost, it’s advisable to get multiple quotes from different providers for your project. Many companies offer online calculators or quote forms where you can input the details of your project to get a rough estimate.

Summary

Understanding the sheet metal laser cutting cost and metal laser cutting cost is crucial for project planning and budget. While the upfront costs can seem higher, the precision, efficiency, and scalability of laser cutting often make it the most cost-effective choice for many applications.

In a world that increasingly values speed and precision, laser cutting stands out as a technology that can deliver both—without necessarily breaking the bank. It’s a robust solution for a wide range of industries, from automotive to aerospace and beyond.

As you plan your next project, keep these factors in mind to get the most value out of your investment in laser cutting services. By doing your homework and consulting with various providers, you’ll be well-positioned to make a choice that balances quality with cost-effectiveness.