In the world of construction, steel structures are indispensable for their strength, versatility, and durability. Particularly in Australia, two vital steel elements play a crucial role in many projects: Trench Mesh and Reinforcing Mesh. Their manufacturing process, marked by precision and stringent quality control, is a marvel of modern structural steel fabrication.

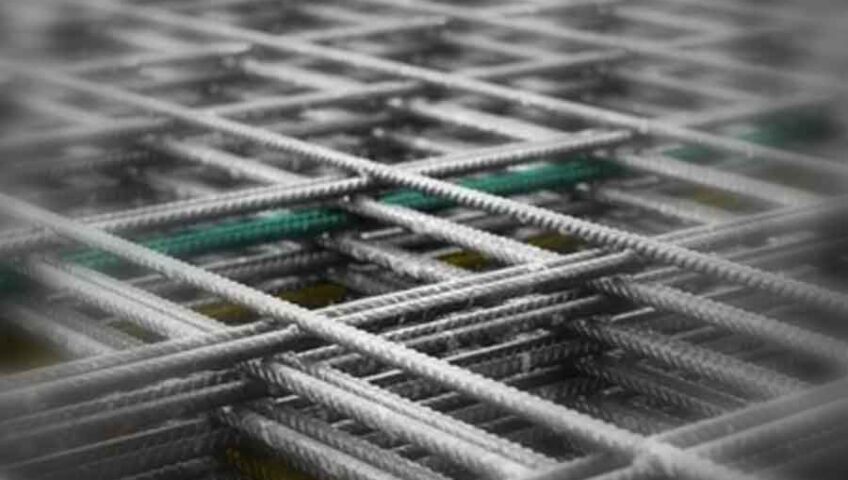

Trench Mesh and Reinforcing Mesh are fundamental components in concrete construction, enhancing tensile strength and overall structural integrity. Trench Mesh is specifically designed for use in residential, industrial, and road reinforcement, typically used in rock walls, brick walls, concrete footings, and other forms of trench structures.

The manufacturing process of both Trench Mesh and Reinforcing Mesh relies heavily on advanced steel fabrication techniques, with welding being a fundamental process. Hot rolling, one of the primary methods, involves heating steel to a high temperature then rolling it into the desired shape. The steel is passed through a series of rollers, which apply pressure and reduce the thickness of the steel, forming it into sheets or wires, the basic form for mesh products.

The welding process, which is the cornerstone of structural steel fabrication, is primarily used to join the steel wires together. Spot welding, the standard process used for this, involves joining steel wires at their intersections using a process known as electric resistance welding. This welding technique ensures a strong bond and high rigidity, making the resulting mesh robust and durable.

In the manufacturing of Trench Mesh and Reinforcing Mesh, quality control is paramount. Regular testing of the raw materials and finished products is performed, ensuring compliance with the relevant Australian Standards, such as AS/NZS 4671 for Steel Reinforcing Materials. Such procedures guarantee that the steel mesh products are of high quality and fit for their intended purpose.

Safety, too, is an integral component of the steel fabrication process. Ensuring the safety of the workers involved in steel fabrication Melbourne and across Australia is a top priority. This includes safe handling and transport of the steel materials, proper use of equipment, and adherence to safety regulations during welding and other fabrication processes. PPE, or Personal Protective Equipment, is also mandatory for workers to protect them from potential hazards in the workplace.

Digital technologies are revolutionizing steel fabrication. For instance, Computer-Aided Design (CAD) is now widely used in the design phase of steel mesh production. It allows for precise and efficient design of mesh products, minimising wastage and ensuring the finished product meets the exact project requirements. Likewise, automation in the fabrication process contributes to increased efficiency, accuracy, and safety.

Another significant aspect of steel structures in construction is their environmental impact. Steel is highly recyclable, making it a sustainable choice for construction projects. Even during fabrication, steps are taken to minimise wastage and reduce the environmental footprint.

Steel fabricators in Melbourne and across Australia continually seek to innovate and improve their processes, adopting cutting-edge technology and adhering to the strictest quality standards. This commitment to quality and innovation ensures that the Trench Mesh and Reinforcing Mesh produced are reliable, durable, and fit for the rigours of construction projects.

In terms of application, Trench Mesh and Reinforcing Mesh play a pivotal role in various construction projects. Trench Mesh is commonly used in narrow and elongated areas, such as reinforced concrete beams and retaining walls, ensuring enhanced strength and stability. Reinforcing Mesh, on the other hand, is widely used in larger concrete constructions such as floor slabs, driveways, and patios, providing necessary reinforcement and preventing crack propagation.

In conclusion, steel fabrication, particularly the production of Trench Mesh and Reinforcing Mesh, is a complex yet essential process in the construction industry. It requires a blend of skilled manpower, precision machinery, stringent safety measures, and adherence to quality standards. The resulting steel structures are integral to many construction projects, providing a balance of strength, flexibility, and durability. Australia’s strict compliance to safety and quality standards, combined with advanced technologies such as CAD and automation, enhances the fabrication process. Structural steel fabrication, including welding, is paramount in this manufacturing. Safety and sustainability remain top priorities, as does the drive for continual improvement and innovation. The roles of Trench Mesh and Reinforcing Mesh are indispensable in construction, from reinforcing concrete beams to preventing cracks in large slabs. Thus, the expertise and innovation in the steel industry not only propel Australia’s infrastructure forward but also ensure its longevity and resilience.