The practice of shaping metal through machining has a long history, dating back to 700 B.C. with manual lathes serving as the primary tool. Fast forward to the 1700s A.D, the advent of steam power ushered in greater efficiencies. The mass production of machine tools revolutionized steel manufacturing processes globally, setting the stage for numerous other advancements. Structural Steel Fabrication, like machining, has similarly evolved. Once reliant on punch cards in the 1940s, today's technology leans heavily on computer-aided systems for programming.

We recognize the critical nature of your manufacturing projects and the inherent risks of potential malfunctions due to subpar materials and inadequate craftsmanship.

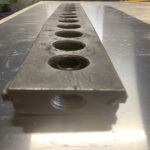

At Humesteel, our flexible approach, supported by our CNC capabilities, allows us to produce a wide variety of machine components. Our commitment to quality and adherence to customized OHS policies ensures that we meet the specified tolerances and minimize errors. To achieve this, we employ a range of specialized techniques and machinery, capable of fabricating large volumes of consistent, high-quality parts.

From fabricating aircraft-grade aluminum alloys to medical bone drills and custom automotive instruments, precision machining and Stainless Steel Fabricatons play crucial roles in constructing assemblies with multiple components.

Our strategy centers on optimization, coordination, and unification. Starting with your unique requirements, we craft bespoke solutions. Customer needs guide every facet of our approach. Whether you require a single component, a full assembly, or a complex multi-part project, we're equipped to fulfill your engineering specifications.

Our in-house team of maintenance fitters at Hume Steel can disassemble your machinery for routine check-ups or repairs. Using our CAD software, we identify and document faulty or worn-out parts. Thanks to our in-house fabrication capabilities, we can efficiently replace those parts and reassemble your machinery, minimizing downtime and getting your production back online as quickly as possible.

Our machining capabilities can be defined as

- Milling

- Threading

- Surface grinding

- Turning

- Drilling

- Cutting, Cropping & Punching

- Bar bending

We can provide laser cut and machined combination parts, multiple process machined parts. We can also provide heat treatment for specific products.

Internal thread cutting solutions from one of part to multiple parts, zinc plating options are also available.