Deeply intertwined with the advancements in technology, laser cutting, a precise and highly versatile tool, has shaped numerous industries. But when was laser cutting actually invented? A glimpse back into history reveals the intriguing journey of laser cutting, taking us to the heart of the mid-20th century.

When was laser cutting invented?

A label printer works by employing one of two printing technologies: thermal or inkjet. Thermal printers, including direct thermal and thermal transfer types, produce labels by heating a special type of paper or using heat to transfer ink from a ribbon onto the label. On the other hand, inkjet printers spray tiny droplets of ink onto the label to create the desired image or text. These technologies allow label printers to produce high-quality, durable labels efficiently.

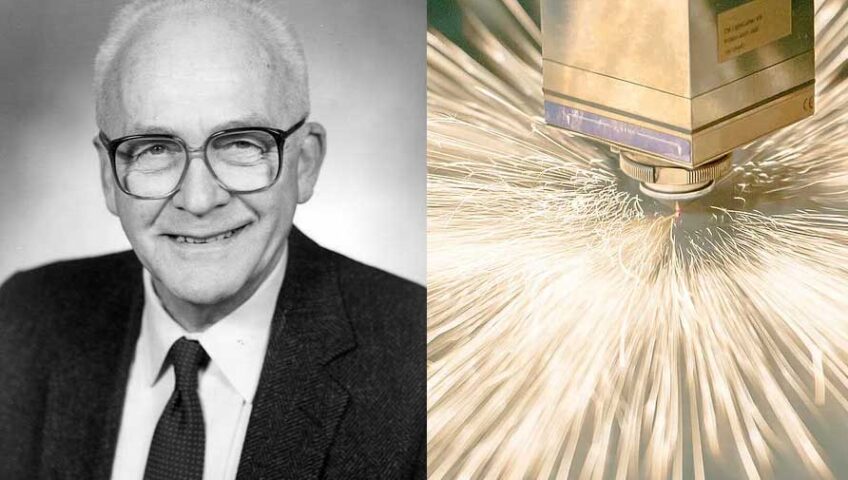

In 1960, Theodore H. Maiman, a physicist at Hughes Research Laboratories in Malibu, California, ignited the dawn of the laser era. He successfully created the first ruby laser, a device capable of producing a beam of light with extraordinary properties. However, Maiman’s invention didn’t directly lead to the birth of laser cutting.

The initial stages of laser development were primarily focused on the demonstration of laser properties, not on its practical applications. In fact, it was only several years later, in 1965, that Western Electric Engineering Research Center introduced the concept of laser cutting, marking the true inception of this technology.

Western Electric, an entity of the AT&T Corporation, was the first to explore the laser as a cutting tool. They developed a system that used the concentrated beam of a laser to cut through diamond dies. It was a monumental milestone that opened new doors to a world of possibilities.

The potential of laser cutting was quickly recognized across various industries, prompting further developments. In 1967, just two years after its introduction, a British engineering company named TWI commenced work on a laser cutting machine, using oxygen and a CO2 laser. It was this venture that led to the first industrial application of laser cutting.

The evolution of laser cutting saw an array of developments. By the 1970s, CO2 lasers were becoming the industry standard. The decade witnessed the widespread adoption of this tool, reshaping sectors from automotive manufacturing to medical equipment production. The 1980s and 1990s saw the introduction of 2D and 3D laser cutting systems, further revolutionizing the manufacturing landscape.

As we entered the 21st century, laser cutting technology became more sophisticated, leading to the invention of fiber lasers. The first commercial fiber laser cutting systems, introduced in the early 2000s, offered unprecedented speed, precision, and versatility. They opened up new frontiers for applications in sectors such as electronics, aerospace, and renewable energy.

Modern laser cutting machines

Modern laser cutting machines now include features such as high-speed linear motors, 5-axis systems, and even steel laser cutting capabilities. The ongoing developments in software, such as nesting programs and CAD/CAM systems, have also improved the efficiency and versatility of laser cutting.

The global laser cutting machine market size, valued at USD 4.09 billion in 2020, is expected to grow at a compound annual growth rate (CAGR) of 3.5% from 2021 to 2028. This growth projection reflects the increasing adoption of laser cutting in industries such as automotive, aerospace, and electronics, where precision and efficiency are paramount.

The future of laser cutting, seemingly limitless, will undoubtedly continue to shape and innovate numerous industries. Already, we’re witnessing developments in ultrafast lasers, those operating in picosecond and femtosecond durations, promising further leaps in precision and speed.

In summary, the journey of laser cutting began in 1965, a technological leap made possible by Western Electric Engineering Research Center. This powerful tool has evolved dramatically since its inception, with innovations such as CO2 lasers, 3D laser cutting systems, and fiber lasers marking key milestones in its advancement. As laser cutting technology continues to progress, we eagerly anticipate the revolutionary transformations it will bring across industries, ensuring an ever-evolving, dynamic future.